blown film machine pdf

Constant film tension windup system For either single-station windup or two-station windup A sensor detects the film roll diameter and adjusts the torque drive accordingly Film windup tension is constant at all roll diameters Roll. 8 3 December 1979 Question No2 reads as follows.

Aba Plastic Film Blowing Machine Plastic Film Blow Molding Extrusion

Parker Hannifin Corporation Industrial Gas Filtration and Generation Division 4087 Walden Ave.

. Several billion pounds of polymer mostly. Blown film air cooling Vol. Air ring exit air.

Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according to Butler 1. Lab Blown Film Blending Study Monolayer Films Purpose. Motorized openclose updown Bubble Cage.

WH blown film lines are designed especially for the flexible packaging industry. We are producing blown film lines since 1967 and have consistently set new standards such as the. Groove Feed Barrel and cooling jacket available.

Processing our understanding of the extrusion of tubular blown film remains in the stage of art. Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241. Blown Film Machine CE45-65TT CE55-75TT Features.

Material Reduce film COF add slip Process Keep film tension between 1 and 25 of ultimate tensile strength Equipment Repair worn haul-off nips slippage Realign die idlers. Blown Film Lines for Higher Output Other machine options. It is our hope that this work will serve as a training resource for all.

Manual screen changer. In blown tubular film much controversy exists concerning the effect of air ring exit air velocity vs. Bandera currently managed by Franco and Piero the founders sons has recently focused its product range on two main technologies.

The bottleneck in blown film extrusion lies in the cooling of the fast moving thin melt film It is. This type of extrusion utilizes two or more extruders to melt and deliver a. Lancaster NY 14086 phone 716 686 6400 or 800 343 4048 fax 877 857 3800.

Machine Construction A cut. Blown Film Machine HIGH SPEED TWIN DIE BLOWN FILM MACHINE Features. Blown Film extrusion technology for.

This paper describes the blown film extrusion pro- cess presents the dynamic equations for Pearson- Petrie model discusses some steady-state results ob- tained from the dynamic. At extrusion it forms a liquid tube which is simultaneously drawn in the vertical direction by nip rolls inflated by an internal pressure and cooled by external air rings. Coextrusion of blown film Coextrusion is the extrusion of multiple layers of material simultaneously.

This technique uses air pressure to produce a transverse direction draw and a higher speed haul-off roll speed to provide a machine direction draw. We have tried to add new technology and organize the previous material into an effective format. To Compare Various Types of High Performance LLDPE Film Resins To Determine the Effect of Blending Butene LLDPE into High.

AB Two-layer Co-extrusion Blown Film Machine is used for blowing the plastic laminated film of low density polyethylene LDPE high density Contact Supplier Polypropylene blown film. Blown film extrusion is one of the most commonly used thin gauge fabrication processes for manufacturing plastic films in the world. Blown film is a major processing technique for producing a biaxial melt drawn film.

Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according to Butler 1. The polymer is melted in an. High performance main motor AC inverter drive designed for energy saving and minimum maintenance.

The blown film extrusion process can produce. The tubular blown film process is efficient and economical and can produce a magnifi- cent array of products from a light gauge clear converter film to heavy gauge construction film which.

Blown Film Extrusion Process Explained Amcor Inc

Blown Film Extrusion Line Varex Ii Windmoller Holscher For Hdpe For Pe Multilayer

Blown Film Bandera Plastics Extrusion Italy

Advantages And Disadvantages Of Extrusion Blow Molding Machinery For Plastic Pet All Mfg

Blown Film Extrusion Blown Film Extrusion Process Blown Film Extruders Manufacturers Suppliers Exporters

How To Achieve Cost Savings In Blown Film Extrusion

Aba Blown Film Machine What S The Advantage Polystar Machinery

Three Layer Aba Blown Film Machine Polystar Machinery

1 Schematic Of The Film Blowing Process Download Scientific Diagram

Three Layer Aba Blown Film Machine Polystar Machinery

Blown Film An Overview Sciencedirect Topics

Blown Film Extrusion Quality Assurance

Aba Blown Film Machine What S The Advantage Polystar Machinery

Blown Film An Overview Sciencedirect Topics

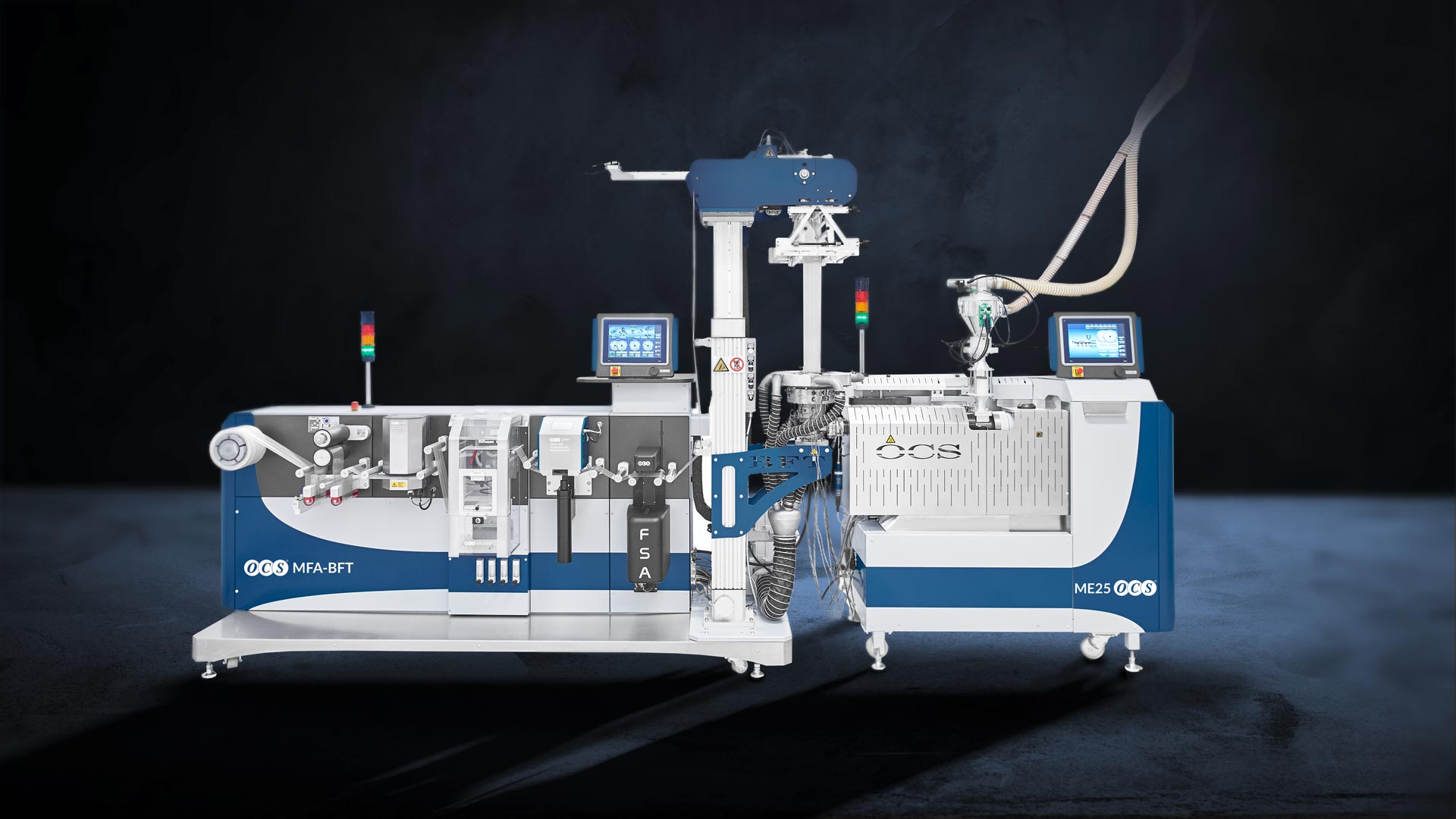

Blown Film Line Ocs Optical Control Systems Gmbh

Aba 3 Layers Co Extrusion Blown Film Machine Youtube

Blown Film An Overview Sciencedirect Topics

Plastar Blown Film Machine Manufacturer

Microinjection Molding Is Used To Manufacture Highly Valued Micro Medical Components Such As Sensors Plastic Injection Molding Mould Design Plastic Injection